An offer recently came our way that was just too good to refuse. One of our favorite Virginia breweries, Pale Fire Brewing, needed help inspecting their new cold room. Since their brewery is within walking distance of the Ivy Tools office, I think I blurted out something like, “Would now work? Great, I’ll be right over!” So much for keeping it professional.

An offer recently came our way that was just too good to refuse. One of our favorite Virginia breweries, Pale Fire Brewing, needed help inspecting their new cold room. Since their brewery is within walking distance of the Ivy Tools office, I think I blurted out something like, “Would now work? Great, I’ll be right over!” So much for keeping it professional.

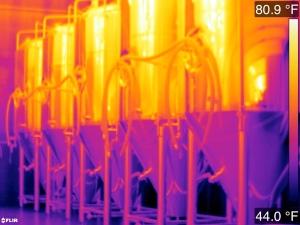

Pale Fire stores their beer at 38 degrees F to ensure both freshness and proper flavor. The beer is born in the brew house, then makes its way to the fermentation hall, the packaging hall, and ultimately lands in the cold room. From there it will be loaded onto trucks for distribution. (Ironically, Pale Fire is located in a renovated early 20th century ice storage facility. By some unfortunate twist of fate, the brewery cold storage room doesn’t overlap with any of the original ice storage areas.)

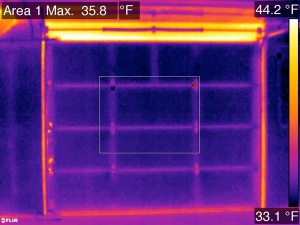

A brewery cold room, like any cold storage facility, faces challenges. Since you need to keep it at a considerably lower temperature than any other space in the brewery, heat is constantly trying to elbow its way in. This could result in large utility bills or quality variation due to uneven temperatures. Furthermore, one wall of the Pale Fire cold room is an outside wall, opening onto a loading dock. This means the room also has to contend with humid Virginia air in the summer. Too much moisture traveling through the walls may result in condensation, which will degrade the insulation, make the refrigeration system work harder, and possibly result in unwelcome microbial conditions. So it comes down to insulation and airflow. A good cold storage facility will have consistent, uninterrupted insulation, and will allow little uncontrolled airflow from adjacent areas.

To bravely answer the call, we took our FLIR T420 thermal camera over to Pale Fire to have a look at the recently completed keg room. The room had been at a steady temperature of 38 degrees for several days. What we found was a room that performed reasonably well. The biggest opportunities for improvement concerned airflow around the doors entering from the packaging hall and loading dock. A little adjustment and some weatherstripping will go a long way here. If the room underperforms over time, a blower door test may be in order to further trace air infiltration. Seasonal temperature and humidity fluctuations may also bring new challenges and solutions.

As the weeks have passed, the new cold room is up and running, keeping the kegs at a steady 38 degrees. Using an undisclosed but very scientific sampling method, I’d say the beer is doing just fine….