People ask us all the time, “Which thermal imager is right for me?” We love answering this question. The answer of course depends on how you want to use the imager (also called an infrared camera, thermal camera, or infrared imager). While there are usually several infrared imagers to consider for any given application, there are also some imagers that will be better than others for that application. Our answer at Ivy Tools to “Which thermal imager?” is based on some combination of the following considerations.

How well a thermal imager creates an image or measures a temperature is primarily an effect of its infrared detector. This is the piece of hardware that detects infrared energy coming through the lens. Simplifying a bit, we are concerned with two aspects of the detector: sensitivity and resolution.

How well a thermal imager creates an image or measures a temperature is primarily an effect of its infrared detector. This is the piece of hardware that detects infrared energy coming through the lens. Simplifying a bit, we are concerned with two aspects of the detector: sensitivity and resolution.

Sensitivity

Sensitivity refers to how well the detector can detect infrared energy- related to how sensitive it is to temperature. One thermal imager may be sensitive to 0.10° C, while another may be sensitive to 0.05° C temperature changes. The more sensitive detector will see smaller temperature variations and use this information to create a sharper image.

Resolution

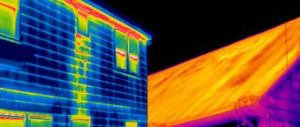

An image is created by taking multiple measurements, converting these to an electronic signal, then displaying the results. The resolution of an imager relates to how many measurements the detector can make. The infrared thermometer (or “spot temp gun”) takes a measurement from one point. It’s resolution is 1×1, or 1 pixel. A thermal imager with a resolution of 120×120 takes 14,400 measurements simultaneously. It can use the different temperatures in those 14,400 pixels to create a meaningful image for the user.

But what about different resolutions? When close to a target, each pixel detects information from a smaller area, giving better detail. As you back away from the same target, each pixel is detecting information from a larger area of the target. You can now see more of the target in the image, yet it has become harder to see small details. This is where a higher resolution imager can help. Just as you can see more detail in a high-definition TV, an infrared camera with a higher resolution can scan a larger area or provide more detail than a lower resolution camera.

Temperature

How high a temperature will you need to view or measure? Or how small a temperature variation might you need to visualize? These are important considerations, as some thermal cameras are designed for certain operating conditions. Take the FLIR Ebx-Series for instance. This is a fantastic line of thermal imagers designed for conditions often found in the built environment. It’s capable of sensing some of the smallest thermal variations, and has a working temperature range of -4° to 248° F. It will make accurate measurements, produce sharp images, and generally make your job easier if these are the conditions you are working under. If you work at a manufacturing facility, however, and need to measure or image an object that’s 500° F, you should consider a different line of imagers- in this case the FLIR E-Series, capable of temperatures up to 662° F. Most manufacturers of infrared cameras now offer this dual approach: one line of cameras for the built environment, and another line for the mechanical and industrial environment.

Other Features

- Digital Camera – Some imagers have a digital camera incorporated, allowing the user to record visible light and infrared images together. This can aid clients or other contractors in locating the problem area. Some thermal imagers can present these digital and infrared images overtop of one another (“picture-in-picture”), or blended together (“fusion”).

- Lenses – When you need to get a close-up image of a target, but can’t physically get there, a telephoto or zoom lens can be indispensable. Similarly, a wide-angle lens can help you inspect more area when in a confined space. If you need these features, be sure to look for an infrared camera with interchangeable lenses.

- Annotation – Depending on the task, it can be cumbersome to carry around a clipboard, and time-consuming to match up written notes with images later. Many imagers can help you record your notes right alongside the image. This can be through voice, text, or even sketching right on a touchscreen.

- Compatible Tools – One helpful feature to many users is being able to wirelessly link together a thermal imager and another tool, such as a moisture meter or ammeter. The imager can add the data from the compatible tool to the image data.

- Connectivity – In recent years the ability to connect an imager to various computer equipment has come a long way. You can now wirelessly connect some imagers to your iPhone, iPad, or Android device. For an unbeatable presentation, some imagers can stream video to a computer connected to a large screen monitor or TV.

- Alarms – When surface conditions are near the dew point, or insulation may be missing in a stud cavity, certain imagers are equipped to sound an alarm.

- Etc. – Other features to consider are durability, laser pointer, digital zoom, the option to change lenses, extra batteries, etc.

As always, please feel free to contact us with any of your thermal imaging questions. Give us a call at (877) 273-2311. Or see some of our thermal imager suggestions by application.